Manufacturing Companies for 112 elbow - High Pressure DN125 Steel Wire Concrete Pump Rubber Hose – Ximai

Manufacturing Companies for 112 elbow - High Pressure DN125 Steel Wire Concrete Pump Rubber Hose – Ximai Detail:

Basic Info

Model NO.

DN125-5"

Head Material

High Mn

Working Pressure

85 Bar

Burst Pressure

250bar

Length

Customized

Color

Black Zinc or Customized

Trademark

Ximai

Transport Package

Standard Export Package

Origin

China

HS Code

841391

Product description………………………………………………………………………………………………………………..

High quality rubber hose

| Name | concrete pump rubber hose |

| Size | DN125(5") / DN100(4") |

| Length | any lengths |

| Reinforcement | 2/4 plies of steel wire |

| Hose ends | 148mm/127mm/122mm,etc |

| Working pressure | 85 bar |

| Burst pressure | 250 bar |

| hose ends | galvanized or painting |

| Application | Schwing,Putzmeister,Kyokuto, Sany, Zoomlion, KCP, JunJin, etc |

Our service………………………………………………………………………………………………………………………………………..

High Quality:ISO9001, CE, CO certifications etc. All components adopt the qualified materials.100% quality check and durable testing for every product before shipment.

Competitive Price

Large scale production and well trained workers reduce cost greatly,Ximai use the Bottom Price to make you become the most competitive seller in your region.One-Stop Shopping

Our major is concrete pump pipe and forged coupling, we also have several partners,supplying related products so that can meet customers’ needs.Short Lead Time

We have power production capacity, produce 1500 sets couplings and 500pcs pipes every day.We can have your urgent orders ready in short time.Standard export package

Our package is in conformity with export requirements.We ensure it’s very safe and firm in the course of shipping.Customer Service

Top sales with professional skills make you never feel difficult to communicate with a factory,all Ximaistaff will stand by you, reply your inquiry and solve your problem, no matter pre-sales or after-sales.

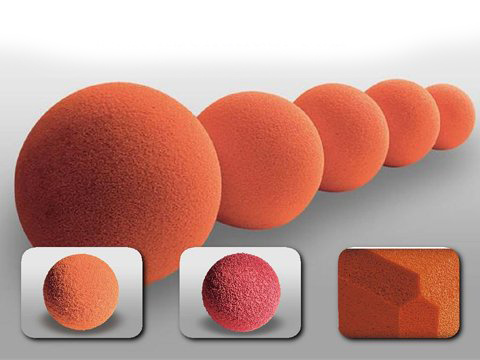

Production display………………………………………………………………………………………………………………………….

Product process…………………………………………………………………………………………………………………………………………

Product process…………………………………………………………………………………………………………………………………………

Product test……………………………………………………………………………………………………………………………………….

Product test………………………………………………………………………………………………………………………………………. Packaging&Shipping……………………………………………………………………………………………………………………………….

Packaging&Shipping………………………………………………………………………………………………………………………………. Contact us……………………………………………………………………………………………………………………………………………..

Contact us……………………………………………………………………………………………………………………………………………..

FAQ……………………………………………………………………………………………………………………………………………………………….

FAQ……………………………………………………………………………………………………………………………………………………………….

Q: Are you trading company or manufacturer ?

A: We are a factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to your quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but the cost of freight by your side.

Product detail pictures:

Related Product Guide:

Our rewards are reduce selling prices,dynamic revenue team,specialized QC,sturdy factories,superior quality services for Manufacturing Companies for 112 elbow - High Pressure DN125 Steel Wire Concrete Pump Rubber Hose – Ximai , The product will supply to all over the world, such as: Peru, Paris, Ethiopia, Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

Send your message to us:

Write your message here and send it to us